Berbica BC Colloid Mill for Peanut Butter Pepper Chilli Paste Ginger butter Making Machine

| Contact parts material: SS304 or 316L |

Support Screw propeller function

|

| With hopper |

Flow 1~4 T/H

|

| Power 11 Kw |

Smallest Emulsification 2um. |

| Production Period. 15 days |

| Packaged by wooden crate |

Some customers know well about Homogenizing, while may not familiar with Colloid mill device. We would like to take this chance introduce you more about it.

A colloid mill is a type of rotor-stator mixer that is often used in the manufacturing of emulsions and dispersions. It can also be used to reduce the particle size of solids in suspension. Colloid mills work on the rotor-stator principle: a rotor turns at high speeds (2000 - 18000 RPM) and pushes the fluid through small holes in a stationary stator, creating extremely high levels of mechanical shear. This process creates a uniform mixture or dispersion regardless of the viscosity of the liquid.

In fact, the application of a colloid mill was narrowed down since it doesn’t have heating system & vacuum system which is required in cosmetic and pharmaceutical industry. The emulsion particles are usually bigger than homogenized emulsions. People can use a colloid mill for pre - mixer, reduce the particles and transfer to another mixing kettle for fine homogenizing or vacuum and heating process. In this way, people can understand it similar to an inline homogenize pump, but it can handle bigger solid particles than inline homogenizing. The raw material for cosmetics and pharmaceutical are mainly powders, which inline homogenize was applied more than colloid mill machine.

Still, colloid mill plays an important role in food industry, process pepper, ginger and garlic etc solid food into sauce / paste. It can also connect to an paddle mixer tank in purpose of adding some food ingredients and flavors and finally process until smooth.

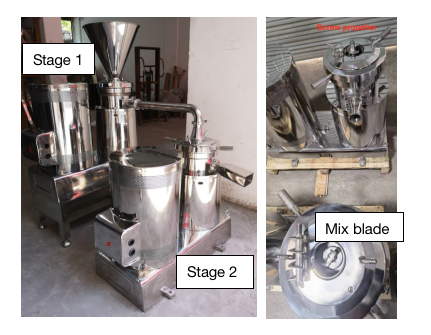

Please review the case of colloid mill we made for our customer in Singapore.

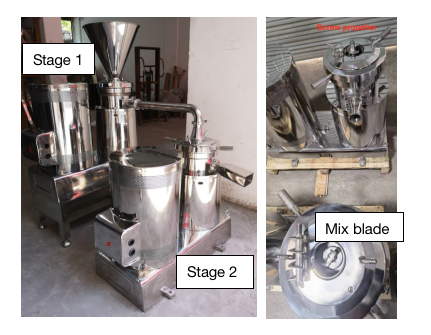

From the photo you can see there are two sets of Colloid mill mixer connected to work together. This is special designed for chilli paste production from dry pepper. Put pepper pieces into the hopper - first stage mill - Second stage mill. The first stage mill equips with screw propeller to help the solid pepper moves into the bottom miller faster. The second stage mill equips rotate blade to help with fast emulsion process. The second stage mill gap is smaller than the first stage mill, emulsification up to 2um. Pepper turns to chilli paste through the two sets colloid mill machines.