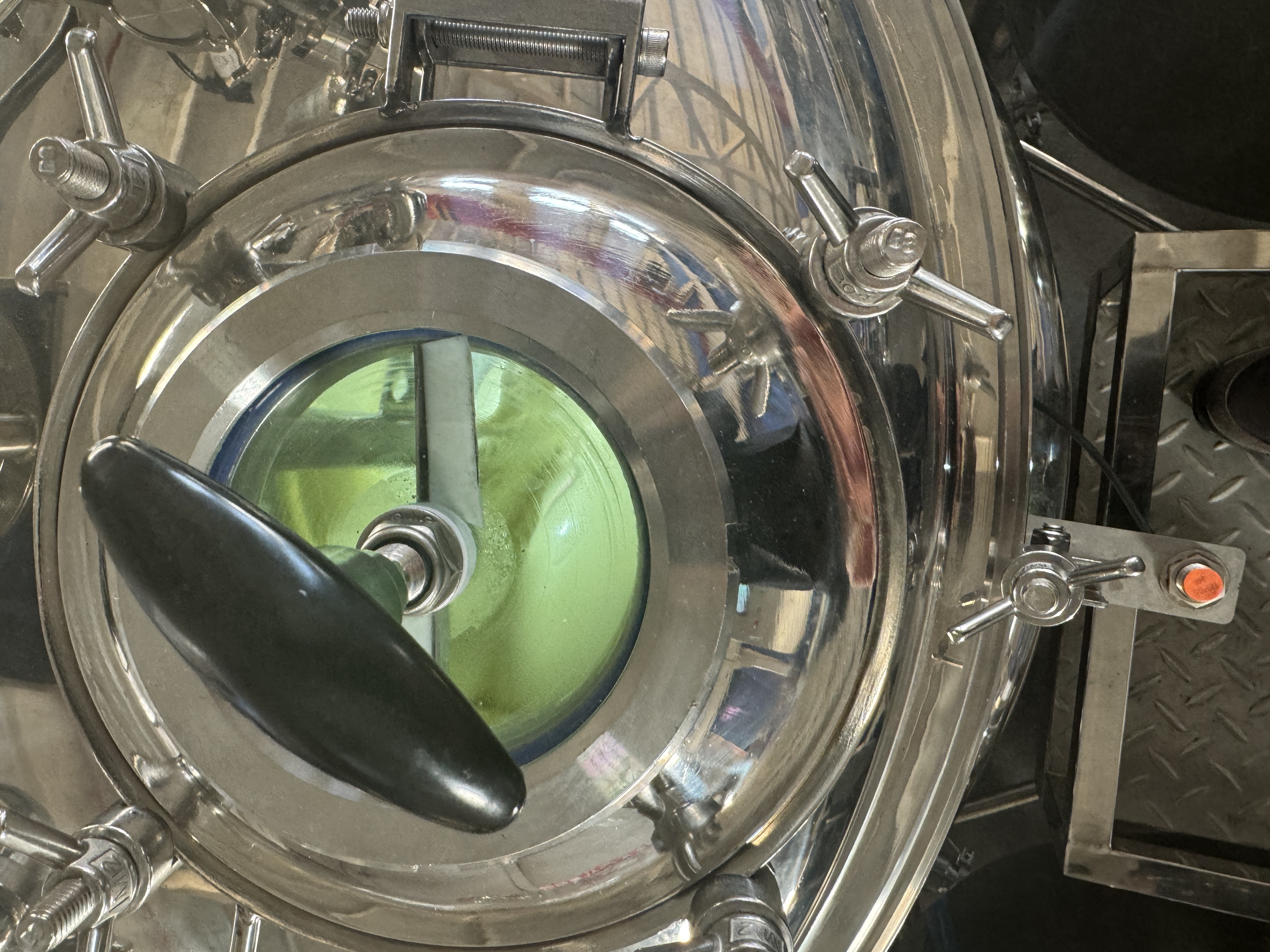

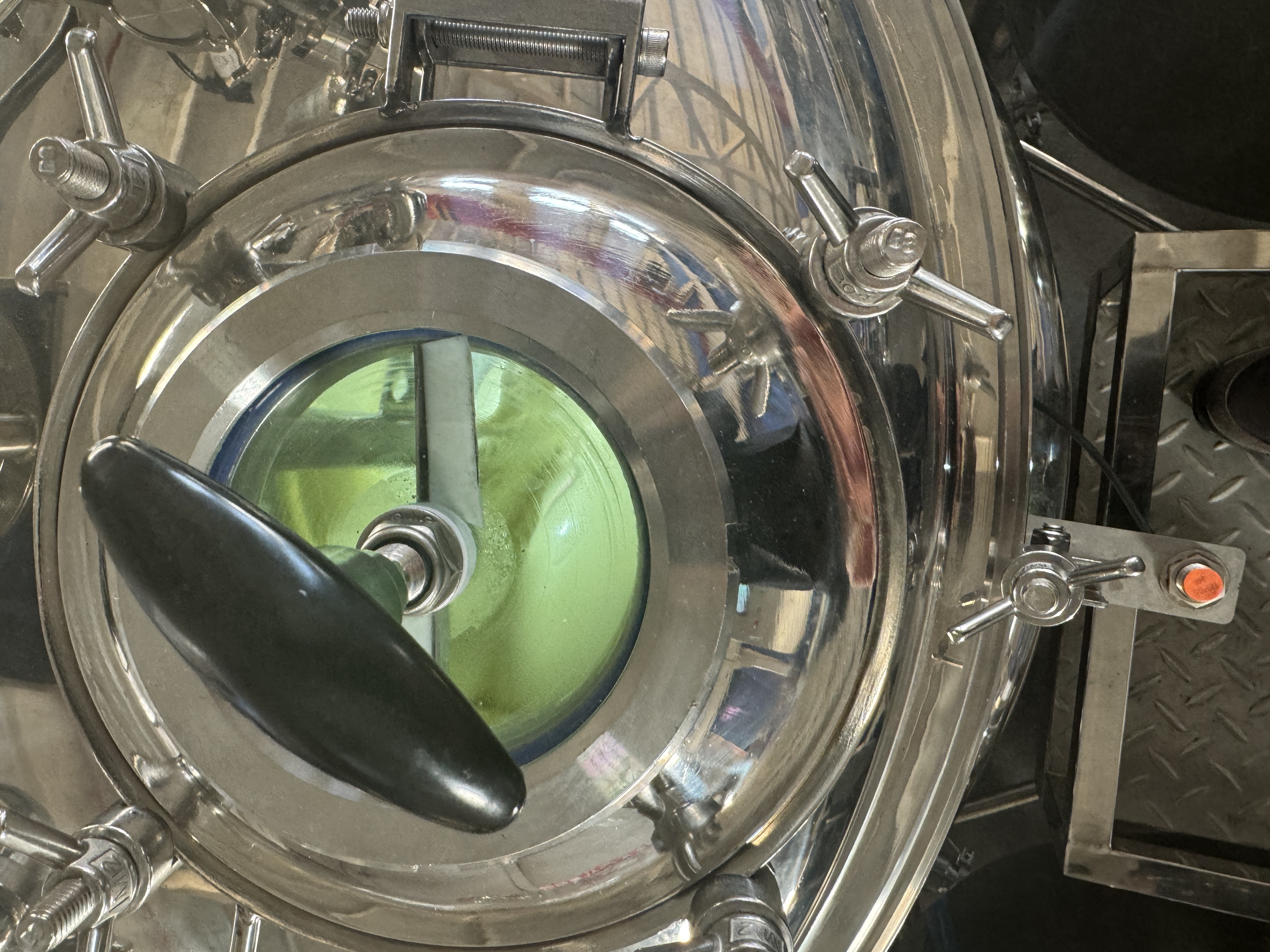

Berbica BSP-700 Mayonnaise Making Emulsifier Machine

Conventional production technology would in fact be able to produce the products. However, it is often impossible to achieve the required product quality in the required time. In BSP Standard Production Plan, which is our independently developed and produced emulsifying mixing production kettle system. The system is highly automated, simple and easy to operate, and monitors the machine running status of each components in a high accuracy standard. BSP benefits from DBI-W emulsifying module, and the modular design makes it easier to maintain or upgrade in the future. It is high end emulsifier design and now plays a very important role in Mayonnaise & Salad production industry.

◆ Modular Design.

◆ Super Compact, shorter standing height, less room space.

◆ High Efficiency.

◆ Higher Viscosity Production Ability.

◆ More Stable Mechanical Structure.

Applications - Food Production Industry - Mayonnaise, Ketchup, Salad sauce, Custard sauce etc.

Cosmetic Industry - Cream, toothpaste etc.

Pharmaceutical Industry - Ointment etc.

The best homogenizer system for mayonnaise.

The best homogenizer system for mayonnaise.

BSP working flow chart on the sample of BSP-700

Model | BSP-5 | BSP-100 | BSP-250 | BSP-500 | BSP-700 |

Full volume(L) | 6 | 120 | 300 | 515 | 500 |

Max. work capacity(L) | 5 | 90 | 230 | 430 | 700 |

Contact material | SUS316/304 | SUS316/304 | SUS316/304 | SUS316/304 | SUS316/304 |

Anchor stirrer power (KW) | 0.25 | 0.75 | 1.1 | 1.5 | 3 |

Stirrer Mixing speed (rpm) | 0~86 | 0~43 | 0~32 | 0~32 | 0~35 |

Homogenize power (kw) | 2.2 | 7.5 | 15 | 15/22 | 22 |

Homogenize speed (rpm) | 0~3000 | 0~3000 | 0~3000 | 0~3000 | 0-3000 |

Vacuum System | Support | Support | Support | Support | Support |

Cover lift and down | Electrical | Electrical | Electrical | Electrical | Electrical |

Cover connections | Watch window, light window, spray ball clean,

vacuum, spare one |

Bottom homogenize

connections | Two material hopper inlets, circulation pipe,

fine product outlet |

The best homogenizer system for mayonnaise.

The best homogenizer system for mayonnaise.